The IGBT 钝化层 (passivation layer) is a critical component in Insulated Gate Bipolar Transistors (IGBTs), enabling their efficient and reliable operation in power electronics. As the world increasingly relies on energy-efficient systems, the role of IGBT devices and their passivation layers has grown significantly. This article provides an in-depth exploration of the IGBT 钝化层, explaining its function, manufacturing process, advantages, challenges, and applications in modern industries. Whether you’re a student, engineer, or enthusiast, this comprehensive guide will enhance your understanding of this essential technology.

What Is an IGBT?

Definition and Function

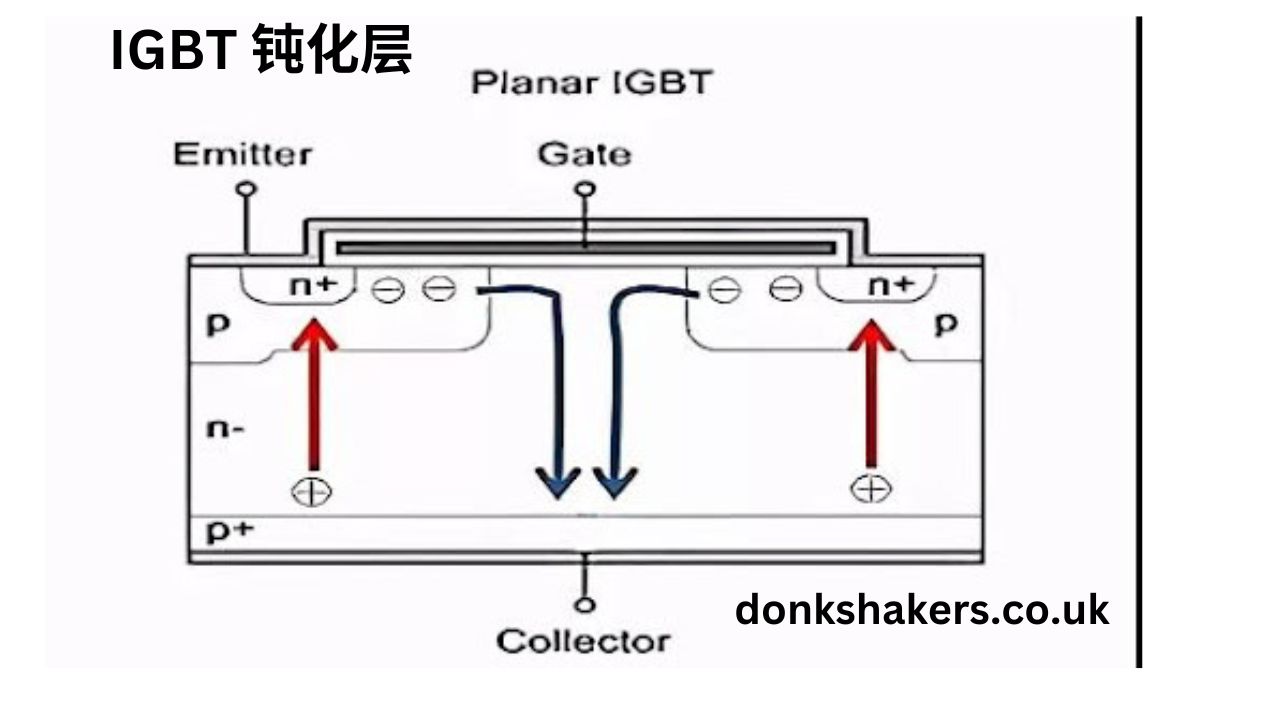

- IGBT stands for Insulated Gate Bipolar Transistor, a semiconductor device used to switch and control high-power electrical currents.

- Combines the fast switching capabilities of MOSFETs with the high-current and low-saturation-voltage characteristics of BJTs.

- Widely used in industrial automation, renewable energy systems, electric vehicles, and consumer electronics.

Key Components of an IGBT

- Gate: Controls the flow of current.

- Collector: Accepts the input current.

- Emitter: Outputs the current.

- 钝化层 (Passivation Layer): Protects the IGBT from environmental and operational stress, enhancing reliability.

What Is the 钝化层 in IGBTs?

Definition of 钝化层

The 钝化层 (passivation layer) in IGBTs is a protective coating that insulates the semiconductor surface, preventing contamination, moisture ingress, and electrical leakage. This layer ensures device stability and longevity, especially under high-voltage and high-temperature conditions.

Functions of the 钝化层

- Surface Protection: Shields the IGBT’s surface from environmental contaminants such as dust, moisture, and chemicals.

- Dielectric Insulation: Prevents electrical leakage and ensures stable operation.

- Thermal Stability: Helps dissipate heat and maintain thermal equilibrium.

- Enhanced Reliability: Reduces the risk of failure due to physical or chemical degradation.

Materials Used in IGBT 钝化层

Common Materials

- Silicon Dioxide (SiO₂): Widely used for its excellent insulation properties.

- Silicon Nitride (Si₃N₄): Provides superior protection against moisture and ionic contamination.

- Polyimide: A flexible organic material used for additional thermal and mechanical protection.

Selection Criteria

- Thermal Stability: The material must withstand high operating temperatures.

- Electrical Insulation: High dielectric strength to prevent current leakage.

- Chemical Resistance: Ability to resist corrosive environments.

- Mechanical Strength: Durability under mechanical stress and vibration.

The Manufacturing Process of IGBT 钝化层

Key Steps

- Surface Cleaning:

- The semiconductor surface is cleaned to remove impurities and contaminants.

- Deposition:

- Techniques like Chemical Vapor Deposition (CVD) or Plasma-Enhanced CVD (PECVD) are used to deposit the passivation layer.

- Patterning:

- Photolithography is employed to create specific patterns for electrical connections.

- Annealing:

- Heat treatment is applied to enhance the material properties of the passivation layer.

- Inspection:

- The final layer is inspected for defects, thickness uniformity, and adhesion quality.

Advanced Techniques

- Atomic Layer Deposition (ALD): Offers precise control over the thickness and uniformity of the layer.

- Spin Coating: Used for organic materials like polyimide.

Challenges in Developing IGBT 钝化层

Thermal Stress

- High temperatures during operation can cause cracking or delamination of the passivation layer.

Electrical Stress

- High voltages can lead to breakdowns in the dielectric properties of the layer.

Material Compatibility

- Ensuring the passivation material adheres properly to the semiconductor substrate.

Miniaturization

- As devices shrink in size, creating thin yet effective passivation layers becomes more complex.

Benefits of a High-Quality IGBT 钝化层

Enhanced Performance

- Reduces power losses and ensures consistent operation under varying conditions.

Improved Reliability

- Minimizes the risk of electrical leakage, thermal damage, and environmental contamination.

Extended Lifespan

- Protects the IGBT from degradation, ensuring a longer operational life.

Cost Efficiency

- High-quality passivation reduces maintenance and replacement costs.

Applications of IGBT 钝化层

Industrial Automation

- Used in motor drives, robotic systems, and factory automation equipment.

Renewable Energy

- Essential for inverters in solar panels and wind turbines.

Electric Vehicles (EVs)

- Enables efficient energy conversion in EV powertrains and charging systems.

Consumer Electronics

- Powers devices like air conditioners, washing machines, and LED lighting systems.

Future Trends in IGBT 钝化层 Technology

Material Innovations

- Development of hybrid materials combining inorganic and organic properties for better performance.

Nanotechnology

- Using nanostructures to enhance thermal and electrical properties.

AI in Manufacturing

- Leveraging AI for defect detection and process optimization.

Eco-Friendly Solutions

- Developing sustainable materials and processes to reduce environmental impact.

Choosing the Right IGBT for Your Application

Factors to Consider

- Voltage and Current Ratings: Match the IGBT to the power requirements of your application.

- Thermal Management: Ensure the device can handle the expected heat dissipation.

- Environmental Conditions: Consider the operating environment, including humidity, temperature, and contamination risks.

- Reliability Standards: Choose IGBTs with high-quality passivation layers for long-term reliability.

Conclusion: The Importance of IGBT 钝化层

The IGBT 钝化层 plays a vital role in ensuring the efficiency, reliability, and durability of IGBTs in modern power electronics. By providing protection against environmental and operational stress, it enables these devices to perform optimally in a wide range of applications. As technology advances, innovations in passivation layer materials and manufacturing techniques will continue to drive the development of more efficient and reliable IGBTs. Understanding the significance of the IGBT 钝化层 is essential for anyone involved in the design, manufacturing, or application of power electronics.