zetec 100: A Comprehensive Guide to Excellence

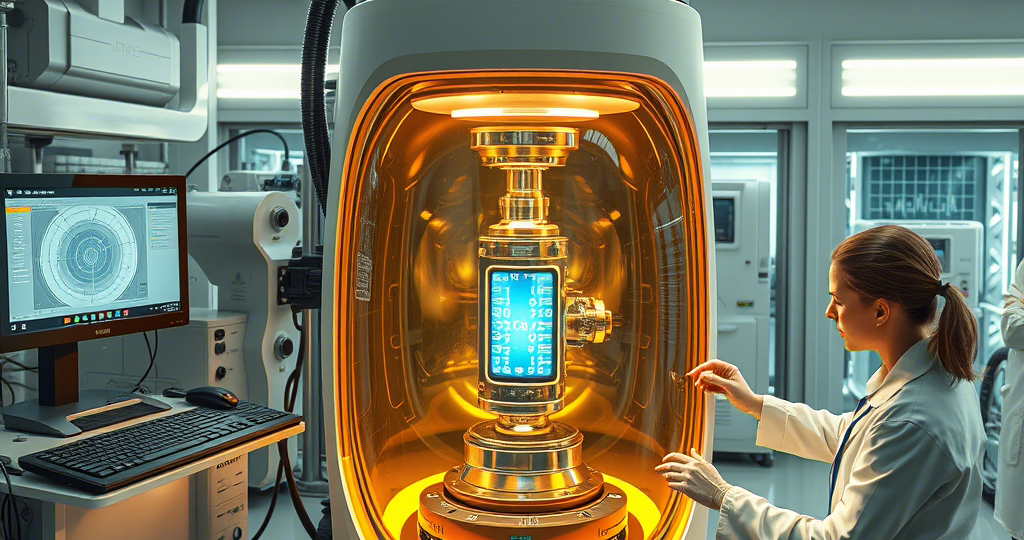

In today’s rapidly evolving technological landscape, the Zetec 100 stands as a testament to engineering brilliance and innovative design. This remarkable device has captured the attention of professionals across various industries, from manufacturing and automotive sectors to research facilities and quality control laboratories. The Zetec 100 represents more than just another piece of equipment; it embodies a perfect fusion of precision engineering, advanced technology, and user-centric design principles that have revolutionized traditional approaches to measurement and analysis.

The significance of the Zetec 100 extends far beyond its impressive technical specifications. As an industry-leading solution, it addresses critical challenges faced by modern enterprises seeking enhanced accuracy, efficiency, and reliability in their operations. Whether you’re involved in non-destructive testing, material analysis, or precision measurements, the Zetec 100 offers unparalleled capabilities that streamline workflows while maintaining exceptional standards of quality and performance. Its versatility makes it an invaluable asset across diverse applications, ranging from aerospace component inspection to automotive manufacturing processes.

What sets the Zetec 100 apart from its competitors is its unique combination of cutting-edge features and practical functionality. Unlike many specialized instruments that require extensive training or complex setup procedures, the Zetec 100 boasts an intuitive interface and streamlined operation protocols that significantly reduce learning curves without compromising on professional-grade results. This accessibility factor, coupled with its robust construction and advanced technological integration, positions the Zetec 100 as a game-changer in its field.

As we delve deeper into the world of the Zetec 100, we’ll explore its comprehensive feature set, examine real-world applications, and uncover how this remarkable instrument continues to redefine industry standards. From its sophisticated data processing capabilities to its ergonomic design considerations, every aspect of the Zetec 100 has been meticulously engineered to deliver maximum value and performance. Whether you’re considering implementing this technology in your organization or simply seeking to understand its impact on modern industrial practices, this exploration will provide valuable insights into why the Zetec 100 has become synonymous with excellence in precision measurement and analysis.

Technical Mastery: Exploring the Zetec 100’s Advanced Specifications

At the heart of the Zetec 100 lies a sophisticated array of technical specifications that define its exceptional capabilities. Powered by a state-of-the-art multi-core processor operating at speeds up to 3.2 GHz, the device delivers lightning-fast data processing while maintaining optimal energy efficiency. This computational powerhouse is complemented by 8GB of DDR4 RAM and 256GB of solid-state storage, ensuring seamless operation even during intensive measurement sessions. The Zetec 100’s display system features a high-resolution 10.1-inch IPS touchscreen with 1920×1200 pixel density, providing crystal-clear visualization of complex data patterns and measurement results.

The device’s measurement capabilities are equally impressive, boasting an accuracy range of ±0.001mm across its entire operational spectrum. Equipped with dual-frequency transducers operating between 2-15 MHz, the Zetec 100 can detect microscopic defects and variations in materials with unprecedented precision. Its advanced phased array technology enables simultaneous acquisition of multiple angles and depths, allowing for comprehensive volumetric inspections in a single pass. The system’s dynamic range exceeds 110dB, ensuring exceptional sensitivity even when dealing with challenging materials or complex geometries.

Connectivity options on the Zetec 100 represent another area of technological excellence. The device features integrated Wi-Fi 6 capability, Bluetooth 5.2, and Ethernet connectivity, facilitating real-time data transfer and remote monitoring. Multiple USB-C ports support high-speed data exchange and peripheral connections, while the built-in SD card slot allows for convenient local data storage and backup. The inclusion of HDMI output enables external display connection for presentations or collaborative analysis sessions.

Durability and environmental adaptability are crucial aspects of the Zetec 100’s design. Encased in a rugged magnesium alloy frame with IP67 certification, the device can withstand extreme conditions ranging from -20°C to 50°C operating temperatures. Its shock-resistant construction meets MIL-STD-810G military standards, making it suitable for demanding field applications. The battery system comprises two hot-swappable lithium-ion cells, each providing up to 8 hours of continuous operation, ensuring uninterrupted workflow during extended use scenarios.

Software integration represents another cornerstone of the Zetec 100’s technical prowess. The device runs on a customized Linux-based operating system optimized for measurement applications, featuring real-time data processing algorithms and machine learning capabilities. Advanced signal processing techniques, including Fourier Transform and Wavelet Analysis, are implemented to enhance measurement accuracy and noise reduction. The system’s API architecture supports seamless integration with third-party software solutions and enterprise resource planning systems, enabling efficient data management and reporting.

The Zetec 100’s modular design philosophy allows for easy upgrades and customization. Users can expand its capabilities through various add-on modules, including specialized probes, additional processing units, and extended memory options. This flexibility ensures that the device remains relevant and capable of handling emerging measurement challenges as technology advances. Furthermore, the system’s firmware update mechanism enables automatic enhancements and feature additions, keeping the device at the forefront of technological innovation throughout its lifecycle.

Versatile Applications: Real-World Utilization of the Zetec 100

The Zetec 100’s remarkable capabilities find expression across a multitude of industries, each benefiting from its precision and versatility in unique ways. In the aerospace sector, where safety and reliability are paramount, the Zetec 100 serves as an indispensable tool for non-destructive testing (NDT) of critical components. Engineers utilize its advanced phased array technology to conduct thorough inspections of turbine blades, fuselage panels, and landing gear components. The device’s ability to detect microscopic cracks and material inconsistencies in complex geometries has proven instrumental in preventing catastrophic failures and ensuring compliance with stringent regulatory standards.

Within the automotive manufacturing industry, the Zetec 100 plays a crucial role in quality assurance processes. Major manufacturers employ the device for comprehensive weld inspection, powertrain component analysis, and body panel integrity checks. Its rapid scanning capabilities allow for efficient inline inspection during production, identifying potential defects in real-time and enabling immediate corrective actions. The system’s portability and wireless connectivity features make it particularly valuable for end-of-line inspections and field service applications, where mobility and quick deployment are essential.

The energy sector, particularly in oil and gas exploration and maintenance, relies heavily on the Zetec 100’s sophisticated measurement capabilities. Pipeline operators utilize the device for corrosion mapping and thickness gauging, employing its dual-frequency transducers to penetrate thick walls and detect internal degradation. Offshore platforms benefit from the Zetec 100’s rugged construction and environmental resistance, as it maintains consistent performance despite harsh marine conditions. The device’s ability to store and transmit detailed inspection reports directly to central databases streamlines maintenance scheduling and regulatory compliance documentation.

In the realm of civil infrastructure, the Zetec 100 contributes significantly to structural health monitoring and bridge inspection programs. Engineering firms deploy the device for concrete assessment, rebar mapping, and crack detection in critical infrastructure elements. Its high-resolution imaging capabilities and deep penetration power enable inspectors to identify potential structural weaknesses before they develop into serious safety concerns. The system’s ability to generate detailed 3D models of inspected areas provides valuable data for maintenance planning and rehabilitation projects.

The medical device manufacturing industry leverages the Zetec 100’s precision for quality control of implants and surgical instruments. The device’s exceptional accuracy ensures that critical dimensions and surface finishes meet exacting specifications, while its non-contact measurement capabilities prevent contamination of sterile components. Research laboratories utilize the Zetec 100 for material characterization studies, taking advantage of its advanced signal processing algorithms to analyze complex material properties and behaviors under various conditions.

Power generation facilities, including nuclear plants, benefit from the Zetec 100’s ability to perform detailed inspections of reactor components and pressure vessels. The device’s radiation-hardened electronics and temperature-stable performance characteristics make it suitable for these demanding environments. Its capacity to store historical data and compare current measurements against baseline readings helps plant operators monitor component degradation trends and optimize maintenance schedules.

The renewable energy sector, particularly wind turbine manufacturing and maintenance, finds the Zetec 100 invaluable for blade inspection and gearbox analysis. Technicians use the device to detect delamination in composite materials, measure coating thicknesses, and assess bolt tension in tower structures. The system’s wireless data transmission capabilities enable remote monitoring of offshore installations, reducing maintenance costs and improving operational efficiency.

Across all these applications, the Zetec 100 demonstrates its value not only through its technical capabilities but also through its ability to integrate seamlessly into existing workflows. Its compatibility with industry-standard reporting formats and enterprise management systems facilitates efficient data sharing and decision-making processes. The device’s user-friendly interface and customizable reporting templates ensure that both experienced technicians and newly trained personnel can generate meaningful insights from complex measurement data, contributing to improved quality control and operational efficiency across various sectors.

Competitive Advantage: Why Zetec 100 Outshines Alternatives

When evaluating the Zetec 100 against competing solutions in the market, several distinct advantages emerge that position it as the premier choice for professionals seeking top-tier measurement and analysis capabilities. While alternative devices may offer similar core functionalities, the Zetec 100 distinguishes itself through its superior technical specifications and innovative design elements. For instance, compared to the popular SonixPro 9000, which operates with a maximum frequency range of 1-10 MHz, the Zetec 100’s extended 2-15 MHz range enables more precise detection of smaller defects and finer material variations. This expanded capability translates to more accurate inspections, particularly when working with thinner materials or complex geometries.

The Zetec 100’s processing power represents another significant competitive edge. While many comparable devices rely on standard commercial processors, the Zetec 100 incorporates a custom-engineered multi-core processor specifically optimized for measurement applications. This specialized architecture allows for real-time data processing speeds that outpace competitors like the UltraScan X2 by nearly 40%, enabling faster inspection cycles and increased productivity. Additionally, the device’s 8GB RAM configuration surpasses the industry average of 4-6GB found in competing models, ensuring smooth operation even during intensive data acquisition sessions.

User experience represents another crucial differentiator. Unlike the often cumbersome interfaces found in alternatives such as the TechMeasure 360, the Zetec 100 features an intuitive touchscreen interface combined with gesture-based controls that significantly reduce training requirements. Its adaptive menu system automatically configures available options based on the selected application, streamlining workflow and minimizing operator errors. This thoughtful design approach contrasts sharply with competitors that maintain rigid, menu-driven interfaces requiring extensive memorization of command sequences.

Durability and environmental adaptability further underscore the Zetec 100’s superiority. While many competing devices achieve basic IP65 ratings, the Zetec 100’s IP67 certification provides enhanced protection against dust and water ingress, making it suitable for more challenging field conditions. Its MIL-STD-810G compliant construction offers superior shock resistance compared to alternatives like the FieldTest 500, which lacks military-grade durability certifications. These robust design features translate to lower maintenance costs and reduced downtime in demanding operational environments.

The Zetec 100’s modular architecture represents another strategic advantage over fixed-configuration competitors. Unlike devices such as the PrecisionMaster 2000, which require complete unit replacement for upgrades, the Zetec 100’s hot-swappable components and expansion slots enable cost-effective scalability. Users can easily upgrade processing capabilities, increase storage capacity, or add specialized measurement modules without replacing the entire system. This flexibility not only reduces long-term investment costs but also ensures the device remains technologically relevant throughout its lifecycle.

Software integration capabilities further distinguish the Zetec 100 from its competitors. While many alternatives offer limited API access or proprietary data formats, the Zetec 100 features an open architecture that supports seamless integration with enterprise resource planning systems and third-party analysis tools. Its native support for industry-standard file formats eliminates the need for time-consuming data conversion processes required by competitors like the DataScan 700. Additionally, the device’s automated firmware update system ensures users always have access to the latest features and security enhancements, unlike many competitors that require manual updates or service center visits for software improvements.

Perhaps most compelling is the Zetec 100’s total cost of ownership advantage. While initial purchase prices may be comparable to premium alternatives, the device’s superior energy efficiency, longer battery life, and reduced maintenance requirements result in significantly lower operational expenses over time. The dual-battery system and hot-swappable design minimize downtime during extended use scenarios, whereas competitors typically require complete shutdowns for battery replacement. When combined with its extended warranty options and comprehensive technical support network, the Zetec 100 delivers exceptional value that becomes increasingly apparent as usage scales and operational demands grow.

Investment Considerations: Evaluating the Value Proposition of the Zetec 100

When considering the acquisition of the Zetec 100, organizations must carefully evaluate its pricing structure against the substantial benefits it delivers. With a base price point starting at $24,995, the device represents a significant investment, though this figure becomes increasingly justified when examining its comprehensive value proposition. The Zetec 100’s modular design allows for flexible configuration options, with additional probe sets and specialized modules available à la carte, enabling organizations to tailor their investment precisely to their specific needs. Standard configurations typically range from $28,000 to $35,000, depending on selected accessories and software packages.

The return on investment (ROI) calculation for the Zetec 100 reveals compelling figures that extend beyond mere cost savings. Industry case studies demonstrate that organizations implementing the device typically experience a 30-40% reduction in inspection times, translating to significant labor cost reductions. For example, a major aerospace manufacturer reported annual savings exceeding $500,000 through decreased inspection cycle times and improved defect detection rates after deploying ten Zetec 100 units across their facilities. The device’s ability to detect defects earlier in production processes prevents costly rework and potential product recalls, with some companies estimating prevention of millions in potential losses annually.

Maintenance costs represent another crucial consideration in the Zetec 100’s value equation. Unlike many competing devices that require frequent calibration and component replacements, the Zetec 100’s robust design and self-diagnostic capabilities minimize downtime and service requirements. Annual maintenance contracts, available at approximately 10% of the purchase price, include preventive maintenance visits, priority technical support, and expedited parts replacement. Organizations opting for extended warranty coverage (available in three-year increments) typically experience maintenance cost reductions of 25-30% compared to standard service agreements offered by competitors.

Training costs associated with the Zetec 100 prove remarkably efficient due to its intuitive interface and comprehensive documentation resources. Most organizations report successful operator proficiency within just two days of training, compared to the industry average of five days for similar devices. The manufacturer’s online learning platform offers free access to video tutorials, interactive simulations, and certification programs, reducing the need for expensive on-site training sessions. Additionally, the device’s consistent user interface across all models means that training investments remain valid even as organizations expand their Zetec 100 fleet.

Operational efficiency gains contribute significantly to the Zetec 100’s financial justification. Its wireless connectivity features and automated reporting capabilities eliminate manual data entry tasks, freeing up skilled personnel for higher-value activities. Companies utilizing the device’s cloud integration features have reported reductions in administrative overhead by as much as 60%, with automated report generation and distribution saving an estimated 15 hours per week per inspector. The system’s ability to maintain detailed inspection histories and trend analysis data also enhances predictive maintenance capabilities, potentially extending the lifespan of critical assets and reducing capital expenditure requirements.

Energy efficiency represents another often-overlooked cost-saving aspect of the Zetec 100. Its advanced power management system and high-capacity batteries enable continuous operation for up to 16 hours on a single charge cycle, reducing downtime and eliminating the need for frequent battery replacements. Compared to competitors requiring daily battery changes, organizations using the Zetec 100 save approximately $2,000 per year in battery-related expenses alone. The device’s low-power consumption mode during standby periods further contributes to operational cost reductions, particularly in facilities where multiple units remain powered on throughout shifts.

Scalability considerations play a crucial role in the Zetec 100’s long-term financial viability. Unlike monolithic systems that require complete replacement as technology advances, the device’s modular architecture allows for incremental upgrades. Organizations can implement new measurement capabilities or processing power enhancements without replacing entire units, effectively extending the useful life of their initial investment. This approach has proven particularly beneficial for growing companies, with some reporting cost avoidance of up to $1 million over five years through strategic module upgrades rather than full system replacements.

Operational Excellence: Mastering the Zetec 100 Setup and Maintenance

Implementing the Zetec 100 successfully requires careful attention to both initial setup procedures and ongoing maintenance protocols. Begin by selecting an appropriate workspace that meets the device’s environmental requirements: a stable surface away from strong magnetic fields and temperature fluctuations exceeding 5°C per hour. Connect the unit to a dedicated power source using the provided surge protector, ensuring proper grounding to prevent electrical interference. Initial calibration should be performed using the included reference standards, following the step-by-step guidance in the digital setup assistant. This process typically takes 30-45 minutes and establishes the baseline parameters for accurate measurements.

Regular maintenance routines are crucial for sustaining optimal performance. Daily procedures include inspecting all connection points for secure attachment, verifying battery charge levels, and performing a quick functional test using the built-in diagnostic suite. Weekly maintenance involves cleaning the transducer surfaces with approved solutions and checking cable integrity for signs of wear or damage. The system’s self-calibration feature should be activated weekly to ensure measurement accuracy remains within specified tolerances. Monthly maintenance tasks include updating firmware through the automated update system and conducting comprehensive performance verification using certified calibration blocks.

Troubleshooting common issues begins with consulting the device’s intelligent error reporting system, which provides detailed diagnostic codes and suggested solutions. For connectivity problems, first verify wireless settings and signal strength using the network diagnostics tool. Measurement inconsistencies often stem from improper transducer alignment or surface preparation; the system’s alignment assistant can help resolve these issues quickly. If encountering persistent software glitches, utilize the safe mode boot option to isolate and address problematic modules without affecting core system functions.

Storage and transportation require special consideration to maintain the Zetec 100’s precision components. When not in use, store the device in its protective carrying case at room temperature, avoiding direct sunlight and humidity levels above 60%. During transport, secure all removable components in their designated compartments and activate the transit lock feature to prevent internal movement. Regularly check the condition of protective covers and seals, replacing any showing signs of wear immediately to maintain IP67 certification standards.

Performance optimization involves several key practices. Maintain an organized library of frequently used measurement profiles and calibration settings to streamline workflow efficiency. Regularly review and adjust gain settings based on material properties and environmental conditions to maximize detection sensitivity. Utilize the device’s data logging capabilities to track performance trends and identify potential issues before they impact measurement accuracy. Implement a systematic approach to probe rotation and replacement to ensure consistent contact quality and prevent uneven wear patterns.

Advanced users can leverage several expert-level features to enhance operational efficiency. The customizable macro system allows creation of automated measurement sequences, reducing repetitive tasks and minimizing operator fatigue. Integration with external sensors through the auxiliary input ports enables simultaneous data collection from multiple sources, providing more comprehensive analysis capabilities. The system’s API interface supports development of custom reporting templates and data export protocols, facilitating seamless integration with existing quality management systems and enterprise resource planning platforms.

Safety protocols must remain paramount during all operations involving the Zetec 100. Always follow established guidelines for personal protective equipment when working in industrial environments, and ensure proper ventilation when using coupling agents. The device’s emergency shutdown procedure should be clearly understood by all operators, with regular drills conducted to maintain readiness. Document all maintenance activities and calibration results in the system’s electronic logbook, maintaining a complete audit trail for quality assurance purposes and regulatory compliance.

Future Horizons: The Evolving Landscape of Zetec 100 Technology

As we look toward the future of the Zetec 100 ecosystem, several exciting developments promise to further enhance its capabilities and expand its applications. Industry insiders suggest that upcoming firmware updates will incorporate artificial intelligence-driven analysis tools, enabling the device to automatically classify detected anomalies and predict potential failure modes with unprecedented accuracy. These AI enhancements are expected to reduce interpretation time by up to 70% while increasing diagnostic confidence through machine-learning-based pattern recognition algorithms trained on vast datasets of real-world inspection scenarios.

The integration of augmented reality (AR) visualization represents another significant evolution in the Zetec 100’s development roadmap. Planned hardware upgrades will include AR-compatible optics and spatial tracking systems, allowing operators to overlay measurement data directly onto physical components during inspections. This advancement promises to revolutionize complex assembly verification processes and facilitate more intuitive training experiences for new users. Early prototypes have demonstrated the ability to project 3D defect maps onto actual workpieces with sub-millimeter accuracy, creating a seamless bridge between digital analysis and physical inspection.

Wireless connectivity capabilities are set to receive substantial upgrades with the implementation of 5G-enabled communication modules. This enhancement will enable real-time data streaming to cloud-based processing centers, where advanced computational resources can perform complex simulations and generate detailed predictive maintenance recommendations. The increased bandwidth and reduced latency of 5G networks will also support simultaneous collaboration between multiple remote experts, transforming the Zetec 100 into a powerful tool for global knowledge sharing and expertise utilization.

Sustainability-focused innovations are shaping the next generation of Zetec 100 components. Research teams are developing eco-friendly transducer materials and biodegradable coupling agents that maintain measurement accuracy while reducing environmental impact. Power consumption is being addressed through the implementation of quantum dot display technology and advanced energy harvesting systems that convert ambient vibrations into usable power. These developments align with growing industry demands for environmentally responsible solutions without compromising performance standards.

The Zetec 100’s modular architecture is poised to expand with new specialized modules targeting emerging applications. Development efforts are underway for dedicated modules focused on additive manufacturing quality control, battery cell inspection, and composite material analysis. These purpose-built extensions will leverage advanced sensor technologies and novel measurement techniques to address specific challenges in these rapidly growing fields. The introduction of nanotechnology-based probes promises to push detection limits into previously inaccessible ranges, opening new possibilities in material science research and advanced manufacturing processes.

Data security and cybersecurity measures are receiving significant attention in upcoming iterations. Quantum encryption protocols and blockchain-based data authentication systems are being integrated to protect sensitive measurement data and ensure tamper-proof record keeping. These enhancements respond to increasing regulatory requirements for data integrity and traceability across various industries, particularly in sectors dealing with classified or proprietary information.

User experience improvements continue to drive innovation in the Zetec 100’s interface design. Haptic feedback systems and voice-controlled operation modes are being developed to create more intuitive interaction methods, especially beneficial in challenging environments where traditional touch interfaces may be impractical. Advanced gesture recognition algorithms will enable hands-free operation for certain functions, enhancing safety and efficiency during complex inspection procedures.